UNI_LINK IS AN INDEPENDENT SOFTWARE PLATFORM TO AUTOMATE THE PRODUCTION, IN THE EXTRUDED ALUMINIUM AND IN THE LIGHTWEIGHT STEEL PROFILES INDUSTRIES.

Its first goal is to be a universal CAM environment, which allows to create macro libraries in a user-friendly way, for operations on working centers independently from the machine.

Secondly, it offers a powerful production list editor, which manages all your production lists and convert them to all the machines of your choice.

Uni_Link is a strong software which manages all your automated tasks. Over 1000 users all over Europe have already relied on our software and benefit from the simple but powerful features which make of the production automation a simple task.

MACRO

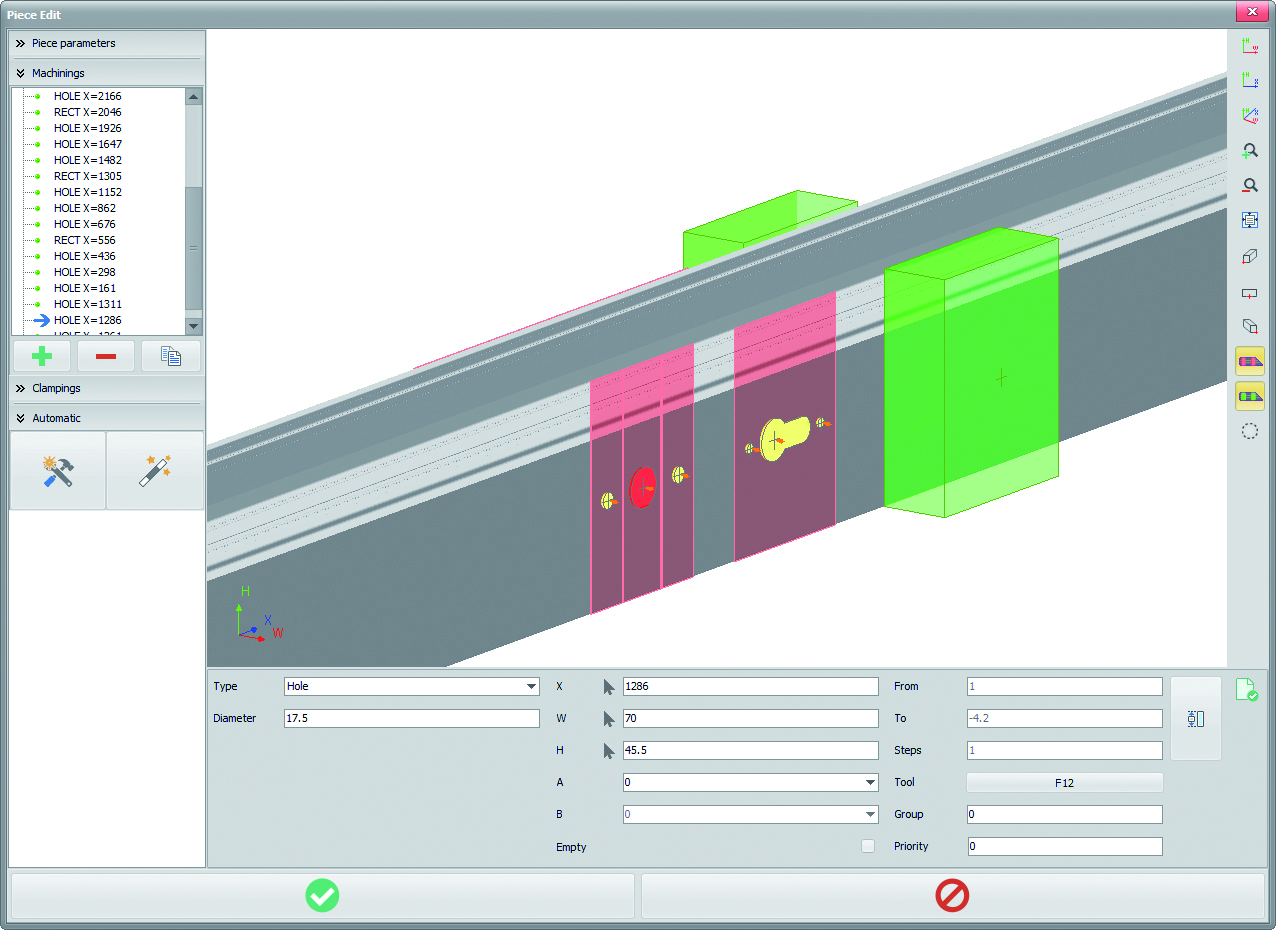

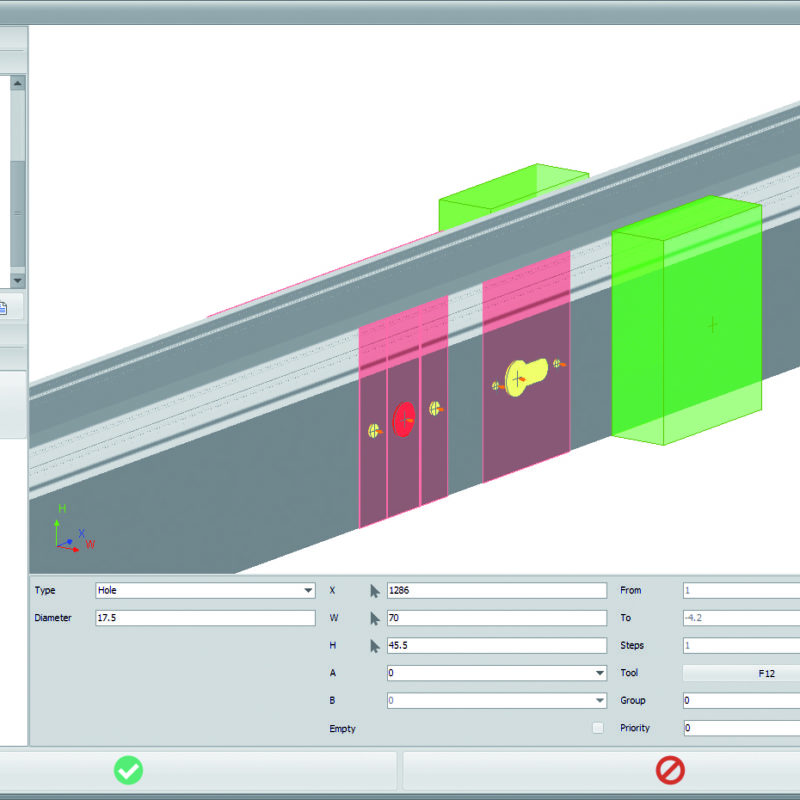

This is the CAM section of the Uni_Link platform.

It is the first vector completely based on CAM software, suited for profile working centers currently on the market. The program consists of a 3D orthogonal system with a 3D visualisation, unlike other CAM available on the market that are composed of several 2D surfaces, with their own coordinate systems.

With Macro it is possible to create a Macro Library in a very short time. When very complex libraries have to be built, the SMART VECTOR option provides extreme powerful features, to build and manage large macro libraries.

This feature is developed for companies that produce and use different profiles.

SCRATCH MANAGEMENT

It is possible to identify damaged spots on the profile bars. With this information the list is optimised to cut out he damaged parts.

DATA IMPORT

The production lists can be imported from every possible source. Uni_Link is compatible with all the construction software for the doors and windows industry. Every data source has its own driver.

STEP FILE IMPORT

It is possible to convert drawings from solid program such as Invertor or Solidworks. On top of it, an intelligent device interprets and modifies the data following given orders.

DSTV IMPORT

A converter reads this old but still frequently used format, which is used to describe profiles with operations.

LIST

This part allows to manage the productions lists.

It is possible to create a production list starting from identified scratches, and to import lists from any source, such as construction software, ERP, 3D Solids, Product Builder etc…

These lists can be edited, merged, split, optimised, managed in all possible ways. Finally, they can be exported to any machine.

CONFIGURATION

All the machines integrated in the production of a company have a configuration file on the Uni_Link platform. During the export, the production list is adapted to the specifications of the machine configuration file. The position of the profile (rotation, mirroring) is taken into consideration, a filter is applied (which regulates which profiles are allowed on the machine) and the tools available are assigned to the operations on the pieces on the production list. This allows a thorough and complete machine management.

All the imports can be configured, to allow perfect coordination and management in the data flow.

Virtual machines can be created through special filters and tasks. Uni_Link’ s strongest features is the fact that everything is highly configurable.

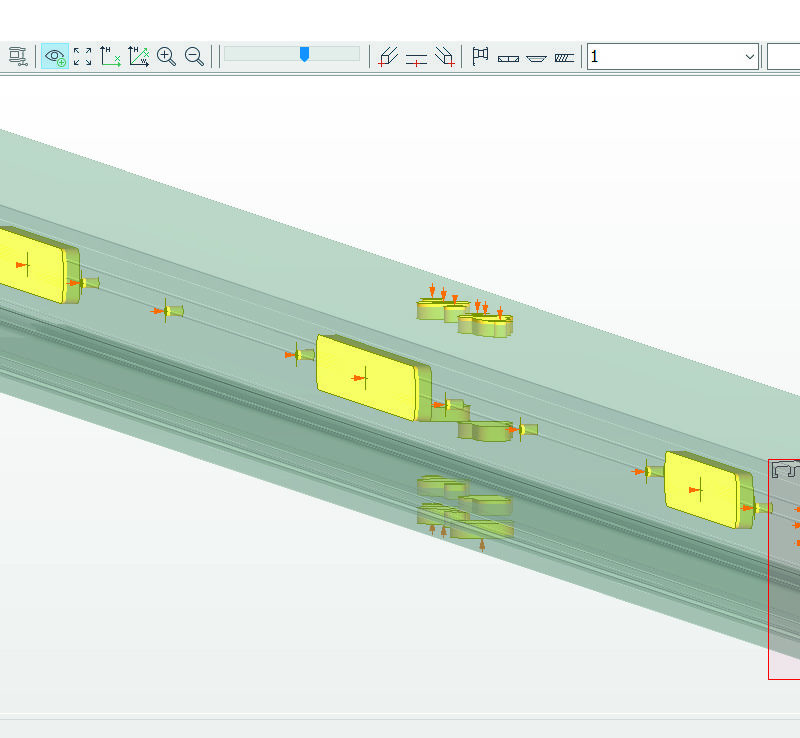

TOOL ASSIGNMENT

The operations that need to be performed on the pieces in a production list do not contain any tool information. When a list is exported to a certain machine, an automatic tool assignment is applied. This means that all the operations are checked and compared to the tools used for this machine, taking into consideration that most of the tools are taken without too many tool changes.

ANTI COLLISION

When the tool-assignment is applied, a graphical anti-collision is automatically performed, to prevent any crush between the toolholder and the profile. In this way, it’s possible to verify directly from the office whether a machine is able to run an operation avoiding collisions, and to determine the tool’s ideal dimensions before starting the machining.

MACRO PRINT

This function allows to have a printout of a profile with its operations on paper or in a DXF file. The drawing can be opened in a CAD software and used for other applications.

PRODUCT BUILDER

This new Uni_Link software allows to create production lists of parametric models, such as fire doors, sun protections, balustrades, conservatories…basically models that are made on a regular basis can be created using different parameters (for example, the dimensions).

Being models based on a powerful scripting language, the possibilities of this software are basically unlimited.

It’s possible to make drawings, as well as partial lists.

Since its release, this software has been really successful and it is used for various applications.

ONBOARD

Recently, Uni_Link has developed a new HMI (Human Machine Interface). This interface is between the machine and the operator, providing to the latter all the informations in a very clear and intuitive way. The many safety controls guarantee safety and reliability. The OnBoard HMI is connected to an open post-processor that is extremely easy to manage. It can be adapted to any machine, with the cooperation of the machine constructor.

TAILOR MADE SOLUTIONS

Uni_Link is equipped with different features, which allow to provide for any automation need. Depending on the request, is possible to create infinite configurations. It can offer tailor made solutions as well.